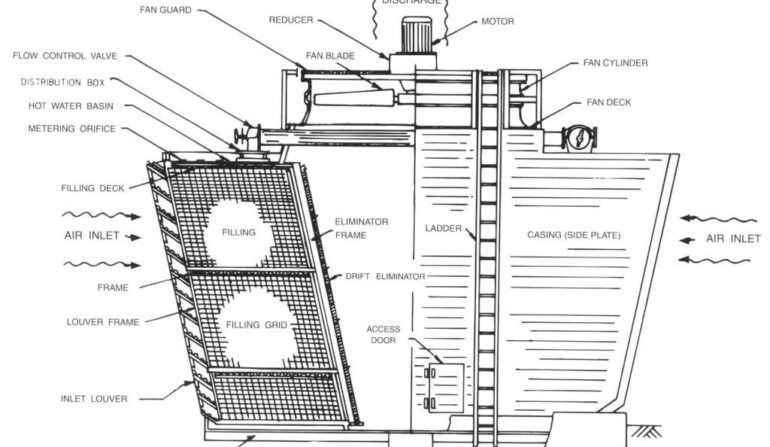

Wooden Cooling Tower

Wooden Cooling Tower design incorporates a RCC basin with number of flower type target nozzles in it and is located at the tower top. The water, by gravity, is dispersed over the fill/splash media uniformly and water is allowed to pass vertically down along these wooden Splash bar. The fan coupled directly to the motor is placed horizontally to draw air across the fill media. A small portion of water is evaporated which removes the heat from the remaining water. In warm moist air is drawn to the horizontally placed fan / motor and is discharged through the fan deck, to the atmosphere. The resultant cold water is collected at the cooling tower collection sump from where it is re-circulated to the application.

Structural Diagram

More Images of Wooden Cooling Tower

Material of Construction

| Item | Material Of Construction |

|---|---|

| Structure | Treated Pinewood |

| Fills | Treated Pinewood |

| Fill Support | SS 304 grid / GRP grids / G.I. grids |

| Drift Eliminator | Treated timber / PVC |

| Drift Eliminator Support | Marine plywood |

| Nozzle | Polypropylene (PP), Polyethylene |

| Hardwares | HDG/S.S. |

| Nails | Twisted SS |

| Fan Assembly | Cast aluminium alloy / FRP |

| Fan Cylinder | FRP |

| Motor | IP 55 |

| Casing and Louvers | Corrugated AC sheet / FRP |

| Cold Water Basin | RCC (by purchaser, as per drawing provided) |

Advantages

- Eliminates fill media, reducing maintenance requirements

- Eliminates motor/fan, thus saving on power consumption

- Suitable for high-temperature applications

- Ideal for industries with polluted waters

- Structure made of HDG steel to prevent rust

- All joints secured with stainless steel fasteners

- Aerodynamic FRP/GI louvers designed for efficiency

- Delta T temperature drop ranging from 4°C to 30°C in a single cell

- Specially designed non-clog nozzles to atomize water into mist

Application

- Automobile Industries

- Cable Industries

- Casting Units

- Cement Factory

- Chemical Industries

- Dairy Industries

- Fertilizers Industries

- Food Industries

- Hotels

- Hospitals

- Paper Industries

- Power Generation Stations

- Petrochemical Industries

- Pharmaceutical Units

- Plastic Industries

- Refineries

- Rubber Industries

- Steel Plant & Rolling Plant

- Sugar Mills

- Textile Mills

- Spinning Mills

- Tyre Manufacturing Units

- Water Effluent Treatment Industries