Square Type Cooling Tower

Square Type Cooling Tower is using principle of counter flow current between air stream and water which is same as induced draft counterflow cooling tower (Bottle Type). The difference is water is distributed by water nozzles installed underneath water distributing pipes. Water distributing pipes are installed above the layer of PVC filler so that hot water is distributed over entire filler cross section area. The cooling air is sucked from bottom of the cooling tower using axial fan installed on top of cooling tower. Air stream moves upward against coming down water. This makes heat transfer between hot water and air. Cooled water will fall into concrete made water basin before being sucked back to reuse again. Either hot dip galvanized steel or FRP extruded profile is used for construction of the tower structure. FRP extruded profile is for more corrosive resistance application. Tower body and fan stack are made of fiber glass reinforced plastic (FRP) as well. This type of cooling tower is suitable for cooling water system which requires higher cooling capacity and higher water flow than our standard cooling tower models. Therefore manufacturing and designing will be as per customer’s requirement.

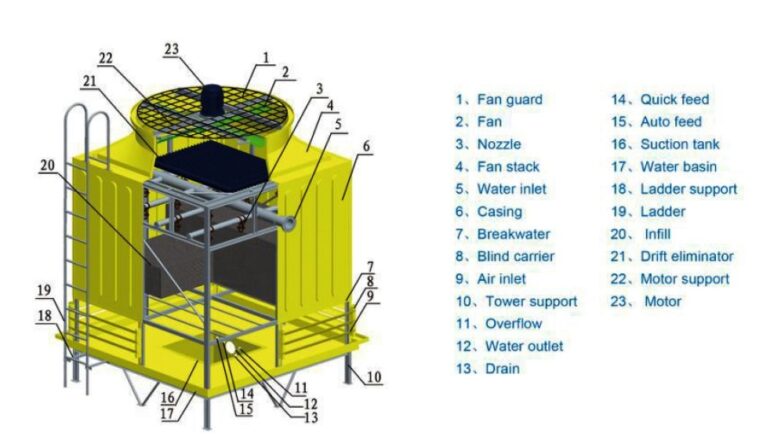

Structural Diagram

More Images of Square Type Cooling Tower

Material of Construction

| Part | Material |

|---|---|

| STRUCTURE | Made of hot dip galvanized steel. All parts are connected with galvanized bolts & nuts. Tower walls are made of glass fiber reinforced plastic. |

| AIR INLET MESH | Made of PE plastic/FRP to prevent foreign material from being sucked into the tower. |

| FAN DUCT | Made of glass fiber reinforced plastic (FRP), installed on top of the tower. Cone-shaped for aerodynamic efficiency and reduced pressure loss. |

| WATER DISTRIBUTION NOZZLE | Used to distribute hot water uniformly on the fills inside the cooling tower. Made of polypropylene. |

| MOTOR | Drives the tower fan; requires a water and moisture-proof type, typically IP 55 rated for standard models, unless a higher rating is required. |

| GEAR REDUCER | Necessary for high airflow; allows the fan to run at lower speeds to reduce tip speed and noise. Gear reducer offers longer life and less maintenance but may be noisier than V-belt drives. |

| FAN | Made of aluminum alloy; creates airflow to enhance water contact with air stream. Axial flow fan is suitable for high airflow, requiring high efficiency, less vibration, corrosion resistance, and safe operation. |

| MOTOR SUPPORT | Made of hot dip galvanized steel; supports the motor and gear reducer securely. Installed on top of the fan duct with a fan guard to prevent accidents. |

| WATER BASIN | Made of fiberglass reinforced plastic; receives cooled water from the filler. Ensures adequate volume to maintain water levels during operation. |

| FILLER | Made of PVC plastic film and corrugated; spreads water over the filler, enhancing heat transfer between water and air stream. |

| DRIFT ELIMINATOR | Made of fiberglass reinforced plastic (FRP); prevents the carryover of small water droplets with the air stream, minimizing water drift loss. |

Features

- Energy Saving Design

- High Performance

- Compactness and Steadiness

- Quick and Easy Installation

Benefits

- Minimum drift loss of water

- Compact structure, light in weight, and corrosion resistant

- Durable and long service life

- Aesthetic designs

- Minimum piping cost and most suited for small industrial units

- Low maintenance

- Free of contaminants like dust or foreign particles

- Higher efficiency (rate of cooling)

- Specially designed fan and tower body to minimize noise

- Use of corrosion-proof high-efficiency filling by the tower

- Leak-proof water collection sump to avoid water spillage

- The ‘bottle’ type structure is highly resistant to strong winds