Introduction

High-Turbulence Transfer is a principle in heat transfer that focuses on the creation and utilization of turbulent flow to enhance the efficiency of thermal systems. In a heat transfer process, achieving effective heat exchange between two fluids—whether heating or cooling—often depends on how well the fluid can interact with heat transfer surfaces. Turbulence is a phenomenon characterized by chaotic and irregular fluid motion, which disrupts the thermal boundary layer and increases mixing. By intensifying these fluctuations, high-turbulence transfer results in improved heat transfer coefficients, faster heat dissipation, and reduced thermal resistance, allowing heat to be moved more effectively from one medium to another. This principle is particularly beneficial in applications where heat must be transferred in a compact space or where energy efficiency is paramount. Industries such as HVAC, automotive, chemical processing, and energy recovery have embraced high-turbulence transfer to optimize their systems. By incorporating turbulence, engineers can significantly improve system performance without requiring larger, more expensive heat exchange surfaces. High-turbulence transfer is vital for systems that need to perform well under high heat flux conditions or with limited space for cooling systems.

Key Features of High-Turbulence Transfer

- Turbulent Flow Characteristics:

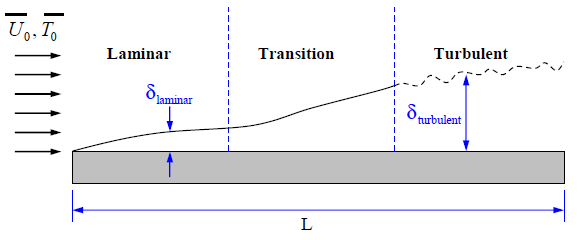

- In high-turbulence flow, the fluid velocity and pressure fluctuations become chaotic, allowing microscopic mixing. This promotes better heat transfer due to the disturbance of stagnant fluid layers near surfaces, known as the thermal boundary layer.

- The chaotic eddies and vortices that form within turbulent flow bring hot and cold molecules into close proximity, reducing temperature gradients and allowing for faster heat exchange.

- Enhanced Heat Transfer Coefficients:

- The heat transfer coefficient (a measure of heat exchange efficiency) is significantly increased in turbulent flow. This is because the mixing caused by turbulence increases the contact between the fluid and heat exchange surfaces, allowing heat to flow more readily between the two mediums.

- High-turbulence flow also helps reduce thermal resistance, meaning more heat can be transferred in a shorter time or with less surface area.

- Boundary Layer Disruption:

- In laminar flow (the opposite of turbulence), a boundary layer of fluid next to the surface does not mix efficiently, thus inhibiting heat transfer. Turbulence disrupts this boundary layer, ensuring that the heat is effectively carried away from the surface and replaced by cooler fluid, facilitating higher heat exchange.

- Compact and Efficient Heat Exchangers:

- With high-turbulence flow, smaller heat exchangers can be designed because the system becomes more efficient. This is particularly valuable in industries where space is limited or high heat flux is required.

- Heat exchangers with enhanced turbulence can maintain high performance even with a reduced size or smaller surface area, which is beneficial in applications like electronics cooling, aerospace systems, and automotive cooling.

Applications of High-Turbulence Transfer

- Heat Exchanger Systems:

- High-turbulence flow is widely used in shell-and-tube heat exchangers, plate heat exchangers, and air-cooled exchangers. These systems benefit from improved heat dissipation due to the increased fluid mixing.

- For example, in HVAC systems, high-turbulence is often introduced in the coolant channels of evaporators and condensers to boost thermal efficiency.

- Industrial Cooling and Refrigeration:

- In industries that require extensive cooling, such as chemical processing, petrochemical refineries, and power generation, high-turbulence transfer improves the rate at which heat is removed from fluids, preventing overheating of sensitive equipment.

- Refrigeration systems benefit from higher turbulence in evaporators and condensers, leading to quicker temperature regulation and higher energy efficiency.

- Automotive and Aerospace Cooling:

- In automotive cooling systems, high-turbulence flow is used to improve the radiator performance and engine cooling, ensuring that heat is dissipated more efficiently in compact, constrained environments.

- Aerospace cooling systems similarly use high-turbulence for managing heat in components like engines, avionics, and hydraulic systems, where maintaining optimal temperature ranges is essential for performance and safety.

- Chemical Reactors:

- High-turbulence flow is vital in chemical reactors where efficient heat transfer is required for controlling reaction rates. It can help manage exothermic reactions and ensure uniform temperature distribution, reducing the risk of overheating or under-reaction.

- Energy Recovery and Waste Heat Systems:

- Energy recovery systems such as waste heat recovery boilers and heat pumps use high-turbulence to capture and transfer excess heat more efficiently. In these systems, high turbulence allows for greater heat recovery efficiency, reducing the need for additional energy inputs.

Benefits of High-Turbulence Transfer

- Energy Efficiency:

- One of the most significant advantages is the reduced energy consumption. High-turbulence flow improves heat transfer efficiency, which means that systems can achieve the desired temperature change in less time and with lower energy input, especially in systems where heat dissipation is critical.

- Reduced Size and Material Usage:

- Due to the high heat transfer rate, smaller systems can be designed, which means lower material costs and less space required. This is particularly useful in industries like electronics (e.g., microprocessor cooling) and automotive cooling systems where space is a premium.

- Cost-Effective Systems:

- The combination of improved thermal efficiency and compact design means that users can achieve significant performance without the high costs of large-scale systems, leading to cost savings on energy and infrastructure.

- Improved Operational Reliability:

- Faster heat dissipation means that equipment is less likely to overheat, resulting in longer lifespan and higher reliability of components like engines, turbines, or sensitive equipment in data centers.

Challenges and Limitations

- Increased Pressure Drop:

- High turbulence can result in a higher pressure drop within the fluid flow. This means that more pumping power may be needed to maintain the required flow rates, leading to higher energy consumption for the pumping system.

- Wear and Tear:

- The turbulent motion of fluid leads to abrasion and erosion of materials, particularly in systems where corrosive or abrasive fluids are used. Over time, this may result in wear on the heat exchange surfaces and other components.

- Complex Design and Maintenance:

- Systems designed for high-turbulence flow can be more complex and harder to maintain. Components may need to be cleaned more often to ensure that turbulence is maintained, and scaling or fouling does not obstruct the flow.

- Noise Generation:

- Turbulent flow can sometimes generate more noise due to the irregular movement of the fluid. This may be an undesirable side effect in applications where quiet operation is required, such as in medical equipment or office buildings.

Conclusion

High-Turbulence Transfer has become a critical mechanism for improving heat transfer efficiency across various industries. By inducing turbulence within fluid systems, it disrupts stagnant layers and promotes better heat distribution, leading to enhanced performance in applications ranging from industrial cooling to aerospace systems. The main benefits—such as higher heat transfer rates, reduced system size, and increased energy efficiency—make it a favorable solution for many modern cooling and heating technologies. However, while high-turbulence flow provides numerous advantages, it is important to address potential challenges such as pressure drops and wear and tear on system components. These issues must be carefully managed to ensure optimal performance and longevity of the equipment. Overall, high-turbulence transfer offers significant promise for future innovations in heat exchange technology, contributing to more compact, reliable, and cost-effective systems across various industrial sectors. As we continue to push for sustainability and efficiency in energy use, high-turbulence transfer will likely play an even more prominent role in the design of advanced thermal systems.