Flat Type Dry Cooler

Flat Type Dry Cooler is a type of heat exchanger designed to dissipate heat from a fluid using ambient air. It operates similarly to a cooling tower but without the use of water for heat rejection. The system consists of a series of flat coils or panels through which the hot fluid flows. Ambient air passes over these coils, absorbing the heat and cooling the fluid in a dry, efficient manner.

Flat Type Dry Cooler can be utilized for the cooling of process liquids such as water or glycol mixtures, particularly in air-conditioning, refrigeration, industrial processes, or other HVAC applications. Available in a wide capacity range, our Dry Coolers are designed to match tight reliability, thermal stability and performance requirements, and capable of operating efficiently in different environmental conditions. Our dry coolers are available in different configurations, including flatbed and V-shaped, and with numerous optional components and accessories.

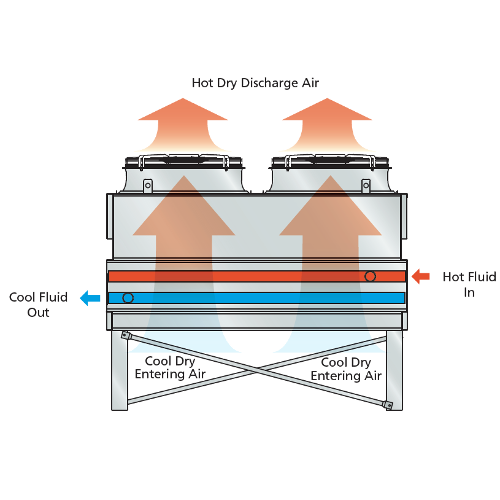

Working Principle

Hot Process fluid enters the inlet header connection, shown in red. Heat from the fluid dissipates through the coil tubes surface and out to the fins. Ambient air is drawn in over the coil surface by the fan located at the top of the unit. Heat from the process fluid transfers to the air and discharges to the atmosphere. Cool process fluid exits the unit through the connections shown in blue.

More Images of Flat Type Dry Cooler

Features

Finned coils:

Built with copper tubes with a 3/8″ ,5/8” diameter and copper tubes with a 1/2″ diameter ., with aluminum corrugated flat fins. High performance rates can be achieved with these coils.

Every coil has passed a leakage test under a rated pressure of 3,923 kPa (40kg/cm2) and pressurized using nitrogen at 147 kPa (1.5kg/cm2) in order to avoid the corrosion of the inner surface of the copper tubes.

Casework:

The structure of the cooling unit’s casing is manufactured in galvanized steel or FRP; its external surface is finished with epoxy-polyester and then baked and cured at 180°C, achieving a high protection against corrosion even under extreme environmental conditions. Metallic protection on connections and return bends.

Fans and motors:

Fans have a diameter of 1050 mm to 1200 mm and they are equipped with external rotor three-phase motors (400V @ 50Hz). Fan make will be Aluminium, FRP or PAG based on customer requirement.

Benefits of Flat Type Dry Coolers

- High-efficiency heat transfer

- Zero water usage

- Reliable

- Low-maintenance

- Corrosion-free

Advantages of Flat Type Dry Cooler

- Operates in dry mode approximately 95% of the year

- Water treatment free

- Full accessibility and maintainability

- No risk of scaling over the coils

- Up to 95% water savings, offered with a water recycling pump

- Plume free

- Low operating costs

- Easy maintenance

- Offers high chiller efficiency compared to dry coolers

- Wide free cooling and dry cooling mode

- Possible option to adapt humidification pads to existing dry coolers