Drift Eliminator for CCT

Drift Eliminators for CCT are crucial components that contribute significantly to the efficient operation of cooling systems. One of their primary functions is to control the escape of vapor and mist from the tower, which helps prevent the loss of valuable water and ensures that the cooling process remains efficient. Without proper drift eliminators, cooling towers would face issues with water wastage and the potential for environmental damage due to water droplets being dispersed into the atmosphere.

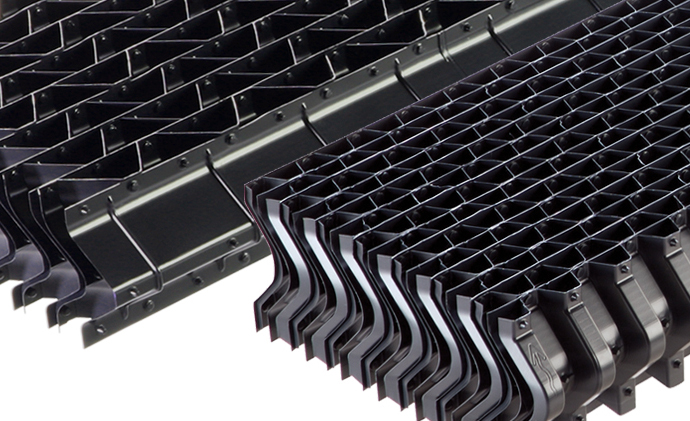

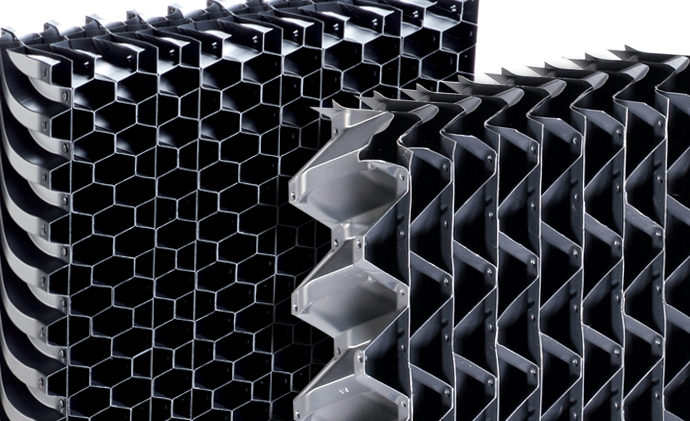

Crossflow Cellular Drift Eliminators are constructed with alternating corrugated and wave-shaped PVC sheets, carefully assembled to form closed cells. This design creates a highly effective structure that maximizes the surface area for water droplet capture within a compact space. The closed-cell design is particularly effective in preventing the escape of water droplets, which improves water conservation and reduces the need for frequent replenishment.

Brentwood’s latest generation of cellular drift eliminators is specifically engineered for crossflow applications, ensuring a high level of drift removal efficiency while minimizing pressure drop. This design allows the cooling tower to maintain optimal airflow and cooling performance while also ensuring that energy consumption remains low.

Benefits of Crossflow Drift Eliminator

- Effectively recycle water and allow controlled release of chemically polluted water from the cooling tower

- Reduce the release of harmful chemicals and toxins into the environment, preventing potential hazards

- High-performance and cost-efficient

- Extend the lifespan and reliability of cooling towers by preventing system and component corrosion

- Conserve energy usage

- Prevent icing on nearby fields and roads

- Drift Eliminators for CCT helps Aid in reducing water loss and emissions