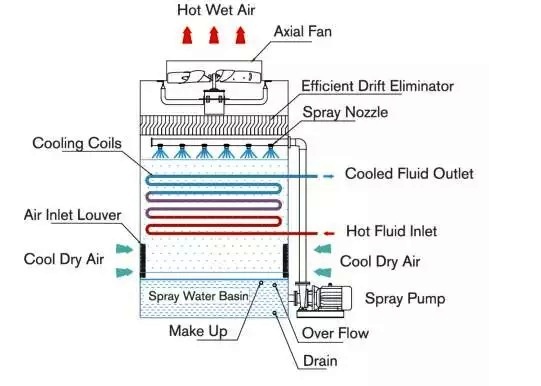

Counter Flow Evaporative Cooler

Counter Flow Evaporative Fluid Cooler is used to Cool the hot water or other Fluid .it works as same induced draft counter Flow t cooling tower principle. counterflow closed circuit cooling tower, the fresh air intakes from bottom air inlet, and will become saturated hot air mixed with spraying water as they flow in reverse direction. The heat will be exhausted out by fans,but the water will be collected to water basin for secondary spraying by its special designed drift eliminator. As no infill inside, cooling tower has much space to enlarge its coil unit heat rejection area, the structure is more compact and requires less footprint. Especially, its suitable to the fluid with high temperature.

Working Theory

As counter flow towers, the dry cool air is inlet through louvers on both sides of the tower from the bottom, and drawn upwards passing a large heat exchange surface of the coils section under the induced fans, against the spraying water in the opposite way, becoming hot wet air, induced draught out of the tower into the atmosphere by the fans on the top. During this process, a part of the heat from the fluids inside the closed loop is transferred efficiently, and removed to the outside environment.

More Images of Counter Flow Evaporative Cooler

Product Features

- Suitable for cooling process water, glycol-water solutions, oil, chemicals, pharmaceutical liquids, machine cooling acids, and other process fluids

- Modular construction allows plug & play installation for new and replacement units

- Saves operational costs compared to conventional systems

- Zero contamination prevents algae formation

- Suitable for lower approach temperature and varied temperature differences

- Offers field-erected units and turn-key solutions with supply of balance of plants

Material of Construction

| Component | Material Options |

|---|---|

| Heat Exchanger Coil | SS 304, SS 316, Carbon Steel, Hot Dip Galvanized Steel, Copper |

| Side Covers | SS 304, SS 316, Carbon Steel, Hot Dip Galvanized Steel |

| Internal Structures | SS 304, SS 316, Carbon Steel, Hot Dip Galvanized Steel |

| Fill Media | PVC |

Advantages of Counter Flow Evaporative Cooler

- No infill design provides a more compact structure, lower profile, reduced installation area requirements, and easy transport and installation

- Suitable for severe environments with a closed structure that prevents sand and dust infiltration, ideal for casting workshops, mining factories, etc.

- Can handle high-temperature fluids as hot spraying water will not distort PVC fill due to the absence of PVC fill

- Freezing resistance, with no PVC fill to slow down the flow speed of spraying water

- Closed circuit cooling systems offer operational and maintenance benefits by keeping process fluid in a clean, closed loop

- Protects process fluids from contamination

- Maximizes system efficiency by reducing fouling and scaling tendencies

- Reduces system energy costs

- Lowers system maintenance costs

- Capable and flexible for customized solutions

- Factory assembled for maximal installation convenience

- Modular design suits a wide range of heat rejection duties

- Compact design with minimal footprints

- Multiple corrosion resistant options

- Low sound operation options available

- More optimizing options available

- Performance and quality guaranteed

- Super long service life