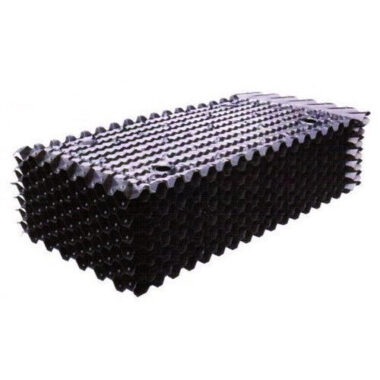

Cooling Tower Fills

Cooling Tower Fills are integral components designed to increase the surface area for heat transfer in a cooling tower. They allow water to spread out more evenly and maximize contact with air, enhancing the evaporation process. The fills are typically made from materials like PVC or wood and are strategically arranged in a pattern that promotes effective heat exchange. By improving the water-to-air interaction, Cooling Tower Fills help optimize the cooling process, making them essential for improving the overall efficiency and performance of cooling towers in industrial, HVAC, and power plant applications.

Crossflow Cross-Fluted Film Fills for cooling tower systems improve water distribution by splitting the water stream as it descends through the fill pack. High thermal performance and low pressure drop are balanced by utilizing the engineered microstructure design and maintaining the highest manufacturing standards.

Specification of Fills

- Material: PVC, PP (available in 100% new material or 80% new material)

- Usage: Cross flow cooling tower

| Dimension | Options |

|---|---|

| Width | 915mm, 1220mm, 1520mm, 815mm |

| Length | 1854mm, 2000mm, 2854mm |

| Thickness | 0.23 – 0.6mm |

Key Factors of Fills

- Greater cooling capacity in a given space

- Low-clog designs available

- Available in bottom-supported or hanging designs

- FM approval available

- Crossflow and counterflow designs

- Integral louvers and eliminators available in crossflow design

- Cooling Tower Fill are High-efficiency and high-quality cooling tower fill with notable advantages